Installing Plumbing and Electrical Services within Insulated Concrete Forms

The lines are cut (or burned out with a hot knife) into the face of the foam in order to secure the plumbing within the system. In those instances, a builder can insert a 1.5-inch diameter line right inside cavity of the foam. However, when a deeper cavity is required, it must be accommodated by special attachments of foam inside the cavity before the concrete is poured. This is basically “blocking” out the cavity to allow for the thicker service.

With Nexcem ICFs:

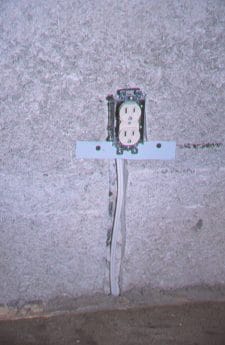

The lines are cut into the face of the Nexcem with a carbide router bit. The Nexcem is 2″ thick and can allow for standard plumbing, wiring and boxes.

Deeper cavities can be accommodated where the webs of our blocks are located as the webs go all the way through the wall.

You can even surface mount electrical work with Nexcem as it has superior surface burning properties and is permitted to be left exposed on the interior.

Read more about the advantages of ICFs here.