Low Carbon Footprint ICFs

What Is The Energy Savings And Global Warming Potential (GWP) Of ICF Walls?

From carbon dioxide to other gases like hydrofluorocarbons (HFC), builders are increasingly paying attention to how to build with a low carbon footprint.

In that sense, GWP offers a better reference point when it comes to assessing the environmental impact of various emissions.

GWP was developed to allow comparisons of the global warming impact of different types of greenhouse gases. Specifically, GWP is a “measure of how much energy the emissions of 1 ton of greenhouse gas will absorb over a given period of time relative to equal emissions of carbon dioxide,” as defined by the Environmental Protection Agency.

While ICFs do have a GWP like most other building materials, it is noteworthy that they simultaneously contribute to a reduction in GWP due to their energy efficiency as well.

In this blog post, then, we’ll discuss two primary dimensions of ICF walls:

- How much GWP is created during the manufacturing process of concrete and expanded polystyrene – the two main components of ICF walls.

- The subsequent reduction in GWP created by the energy savings in the buildings that are built with these same ICF walls.

How Much Global Warming Potential Is Created During The Manufacturing Of ICF’s And How Does This Compare To Other Materials?

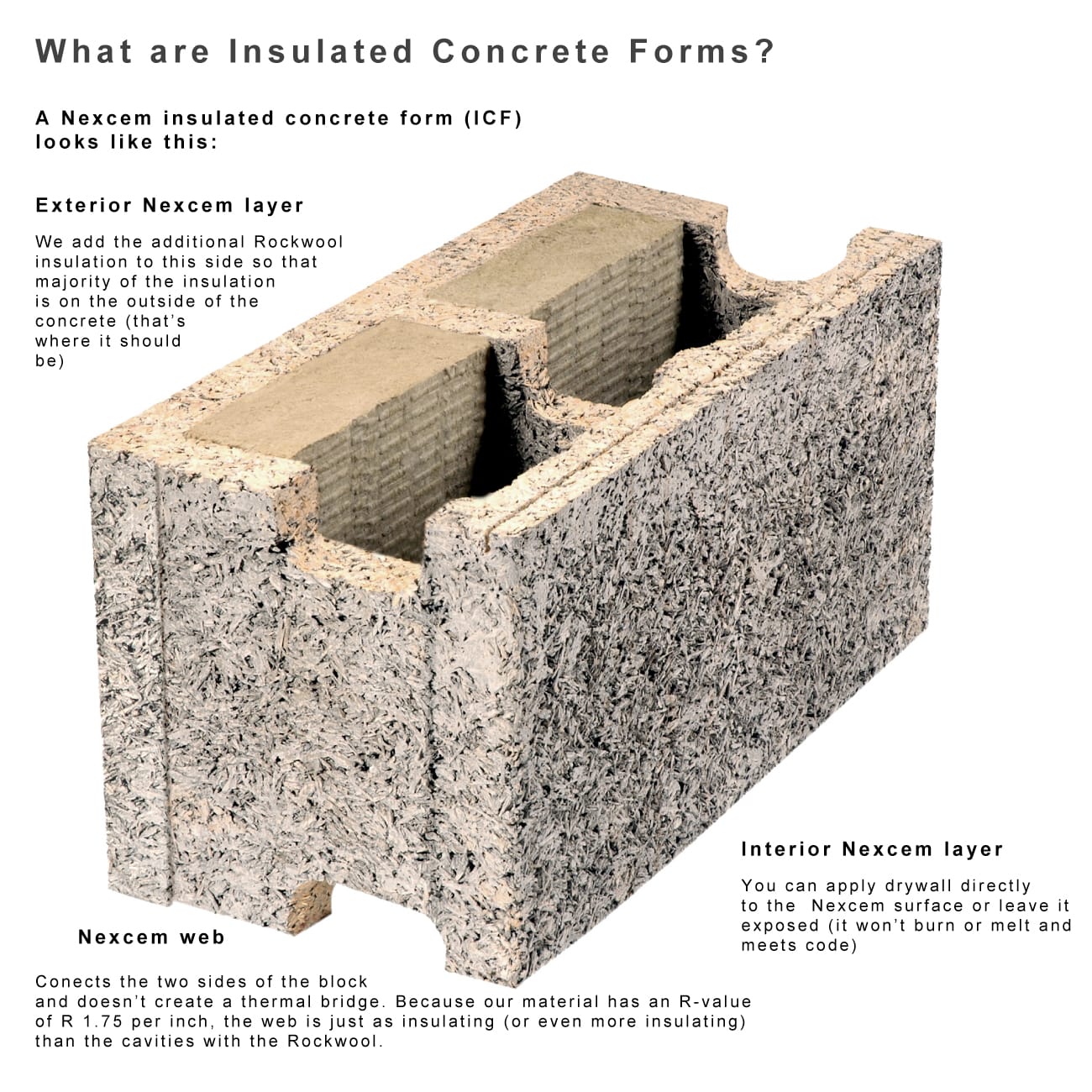

The primary components of a square foot of a typical Nexcem ICF wall is 0.009 cubic metres of concrete, 0.015 cubic metres of Nexcem and 0.009 cubic metres of mineral fibre insulation.

According to the National Ready Mix Association, the embodied carbon in 20 MPA concrete is 214 to 345 kgCO2 per CU meter, depending upon how much “SCM” is in the concrete. (The NRMCA is also reporting a 13% reduction in the overall carbon footprint of their members over the last five years). Mineral Fibre insulation is 1.2 kgCO2 per kg which works out to 1.1 kgCO2 per SF of Nexcem ICF.

The Nexcem material itself has a net embodied energy of 140 kgCO2 per cubic metre or 2.1 kgCO2 per SF of Nexcem ICF

(SCM is fly ash, slag cement, and silica fume. The use of SCM instead of portland cement reduces the carbon load in concrete). Assuming high SCM concrete, the GWP in a square foot of an 8″ deep concrete core of an ICF wall would be 2.34 kgCO2e.

The total GWP of a finished Nexcem ICF at R-28 would be 5.54 kgCO2 per SF of wall area. This is about 10% – 20% less than typical polystyrene ICF systems! Not to mention that Nexcem and mineral fibre insulation are also using very large percentage of recycled material in the first place.

How Embodied Carbon is Offset By the Energy Savings of ICF Walls

Concrete itself provides minimal R-value, but when the concrete core in a Logix ICF wall is sandwiched between the two thick foam panels, it provides a thermal mass effect that amplifies the insulating properties of the foam panels. It is this combination that can save an incredible amount of heating and cooling energy over the entire life of the building.

The Insulated Concrete Forms Manufacturers Association recently conducted a laboratory test to compare the actual thermal performance of an ICF wall with a 2 x 6 wood frame wall. The test results indicated that over the two week testing period, the wood wall would consume 149% more power than the ICF wall. It is test findings like this that support the common anecdotal feedback from ICF homeowners who say they find energy savings of over 50%. If you are building soon you can read more about Passive Homes built with ICFs here.

Of course, if the energy source for buildings today were hydro or solar, those buildings would not generate any carbon. However, we’re a long way from that. (In Canada, for instance, 70% of the energy used for homes and buildings involves fossil fuels with significant GWP). All of this is to indicate that the significant energy savings of the lifetime of a home or building represents a significant reduction in GWP as well.

Bringing it All Together

The above brings us to a discussion of life cycle analysis (LCA). LCA is a method used to evaluate the environmental impact of a product through its entire life cycle. This includes the extraction and processing of raw materials, manufacturing, distribution, use, recycling, and final disposal (in other words, all phases).

This study from the Massachusetts Institute of Technology outlines the relationship between embodied GWP and energy savings for ICF homes.

Wrapping It Up

The GWP in ICFs is offset by energy savings. In this respect, it’s the combination of ICFs’ concrete core and two thick foam panels which result in a very energy-efficiency building envelope, that helps to offset their GWP.

And this is amplified by the sheer durability and exceptionally long service life of ICF built homes and buildings.

More Resources:

- Continuing education course on the environmental impacts of building materials, offered through Hanley Wood University

- Free LCA calculator tool (via Athena Sustainable Materials Institute)

Sources:

https://www.epa.gov/ghgemissions/understanding-global-warming-potentials

https://www.iisd.org/library/emission-omissions

https://www.constructioncanada.net/cement-and-concrete-still-outperforming-in-the-sustainability-era/

Please contact Nexcem professionals for more information on building a net-zero energy home.