As a contractor, at some point you’ve likely considered ICF for your projects. If you remain on the fence about using insulated concrete forms you will want to read ahead to find out why ICF may be the perfect solution for your next build.

5 Reasons Why Your Construction Company Should Consider Insulated Concrete Forms

1. Cost Efficiency

For starters, ICF is one of the most cost efficient forms of concrete building. While the prices of various building materials around the province continues to fluctuate, ICF market prices remain consistent. This stability allows you to provide an accurate quote when negotiating an up and coming project for a client, no matter how far off in the future the build is anticipated to begin. The client will appreciate your ability to standby an estimate. You may have heard that ICF can add initial cost to a build. This may be true, but the resulting home quality, performance and efficiency are usually well worth it. There are also some factors that help balance the initial increased cost. Given that with ICF the building insulation step has been removed from the equation and a significant portion of required skilled-labour is reduced the cost difference is minimized. If your client expresses concern over the perceived cost, they need to understand that the cost of ownership of an ICF constructed building is significantly less that derived from traditional methods. Because insulation is far superior utility expenses are far lower. Every residential/commercial/industrial property owner realizes the longterm financial implications of that. The sturdy construction (more on this below) also minimizes the need for future upkeep and repair to the property, further reducing long term expenditure. In fact, the return on investment (ROI) for the extra construction cost (if any) of ICF is within three to five years. Simply put, when it comes to cost efficiency insulated concrete form construction leads the pack by a long mile.

2. Time Efficient

Insulated concrete forms are about as ready-made as concrete construction can be while remaining customizable to any design feature. There is a learning curve for any contractor adopting ICF construction, but it is a relatively short curve that lasts 1 or 2 projects. The genius of ICF is that while extremely sturdy, blocks and forms are lightweight, allowing your crew to whisk through the foundation installation quickly without excessive energy expenditure. Subcontractors joining the process after the concrete pour will also appreciate the ease of which ICF allows them to do their job. Chases (and other openings) for installation of mechanical systems are cut (with a carbide blade or router) into ICFs without effort. Drywall fastening (or lap siding, etc.) is also expedited. In addition, your crew will appreciate ICF when it comes to corrections that need to be made at any point in the process. An opening can be sawed out and re-formed without significantly setting back the schedule.

3. Sturdy

Insulated concrete forms are load bearing, giving the walls unmatched strength and durability. Think of ICF as a reinforced concrete wall. It is sturdy and far less susceptible to damage than walls constructed from traditionally-poured concrete. As ICF blocks are stacked, structural steel (or rebar wires) are installed inside. When the stacked panels reach the predestined height, concrete is poured into the cavity. An impenetrable and unshakable wall and foundation is created. Whether during the process or after-completion you’ll gain peace of mind in knowing that ICF constructs remain resistant to anything thrown its way – from fires to extreme weather and beyond.

4. Climate Ready

As noted in item #3 above, from a builder’s perspective insulated concrete form walls can take the brunt of any climatic force. Seasonal windstorms, hurricanes, and tornadoes included. And as noted in item #1 (cost efficiency) ICF’s biggest pitch to clients includes thermal buffering that protects properties from outdoor temperature extremes. Air infiltration in an ICF building is also minimal and energy expenditure can be cut in half!

5. Sustainable

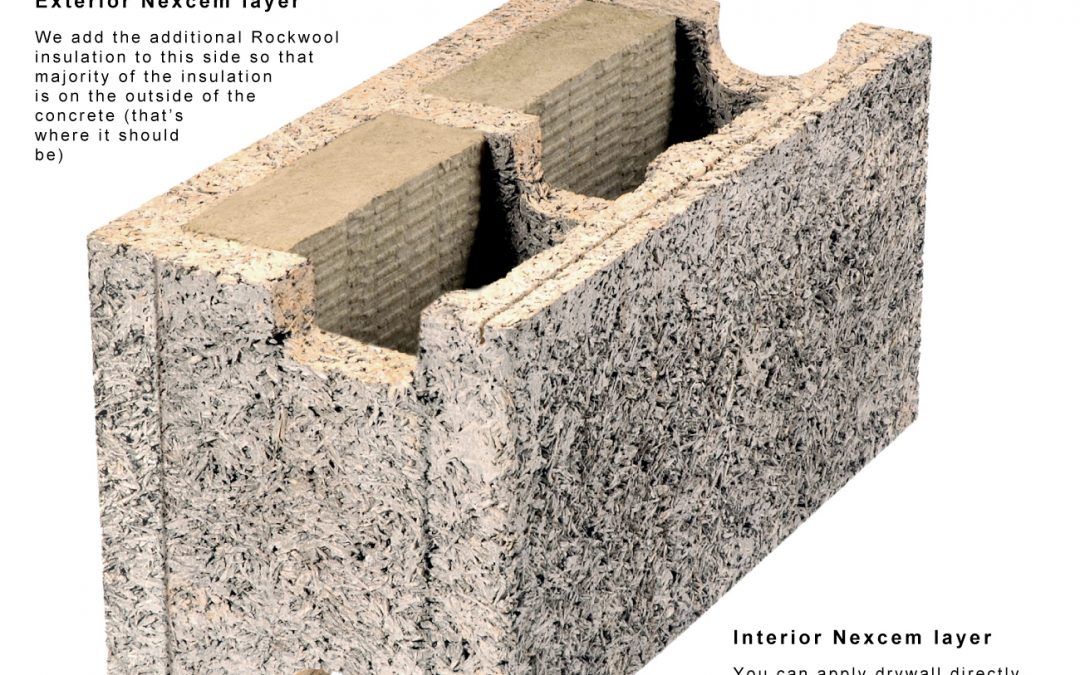

Insulated concrete form construction is more eco-friendly than traditional methods, especially with Nexcem. Made from 80% recycled clean waste wood, it certainly does its part for the environment. Securing Nexcem ICFs for your build also equals LEED credits. The use of recycled materials and significant waste reduction during the construction process contributes to LEED while the longterm energy performance and improved indoor air quality is simply better for the environment and all who reside, function, and/or operate within an ICF build.

Ready to learn more about ICF for your construction projects? Contact us at your earliest convenience.