One of the advantages of building with Nexcem woodcrete ICF is a reduced risk of interstitial condensation.

WHAT IS INTERSTITIAL CONDENSATION?

Interstitial condensation is the technical term for condensation that occurs when moisture-laden air travelling through a wall (through tiny cracks and holes), cools as it gets closer to the outside and then condensing on various surfaces in the wall cavity to form water droplets.

The resulting dampness within the wall cavity is highly damaging. It can rot wooden or corrode steel structural components, soak into specific types of insulation, and lead to mould formation.

Designing your building to reduce the risk of interstitial condensation is vital.

HOW DOES BUILDING WITH WOODCRETE ICF HELP PREVENT INTERSTITIAL CONDENSATION?

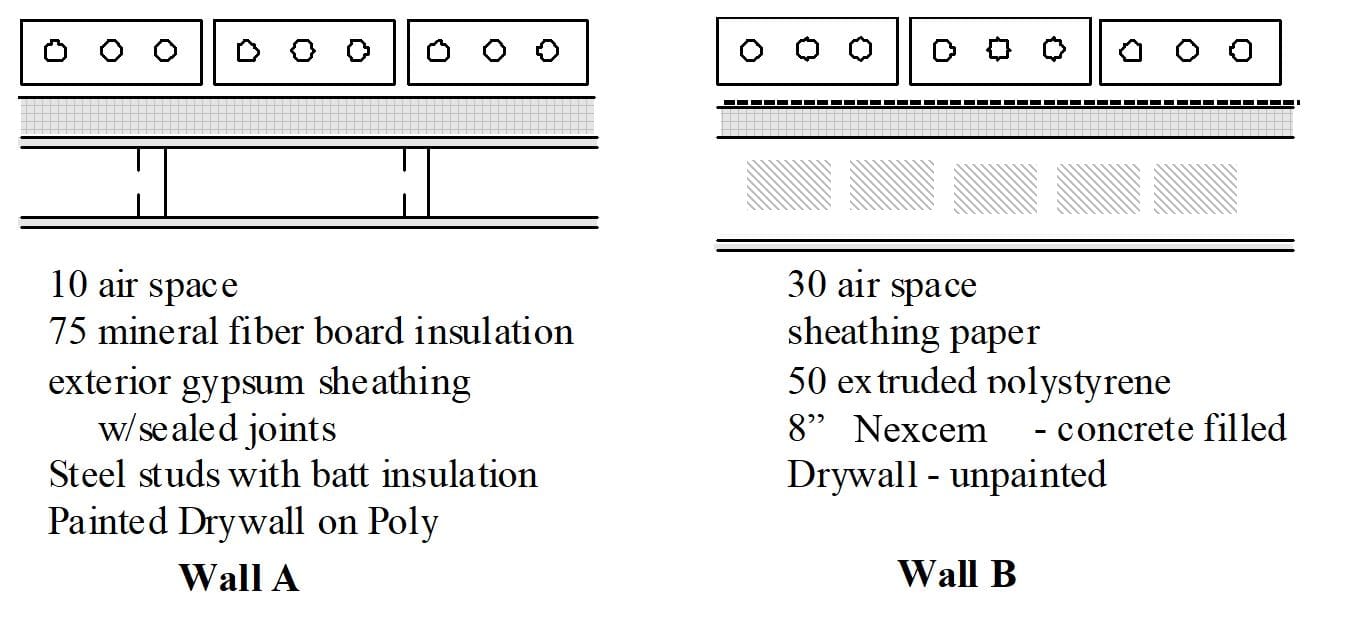

Tests have proven that a solid woodcrete ICF wall is not liable to suffer interstitial condensation. Although computer modelling can be a powerful tool, field measurements are always the best and most reliable means of testing theory. At Nexcem we did both. We tested and monitored two wall systems – the Nexcem Insulated Concrete Form system and a well-built, highly insulated steel stud wall system, both clad with brick veneer. Simplified horizontal sections of the walls are shown below:

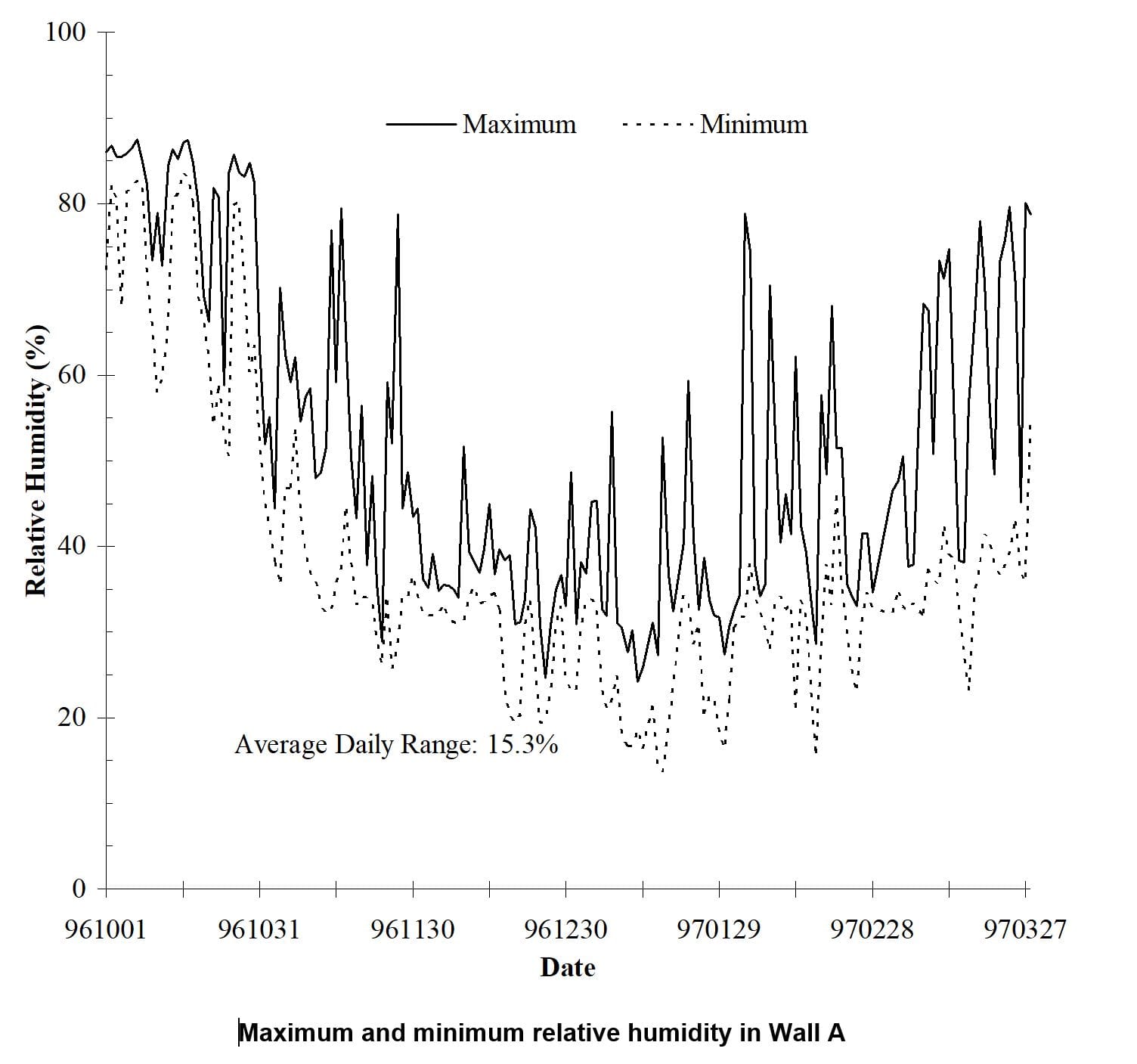

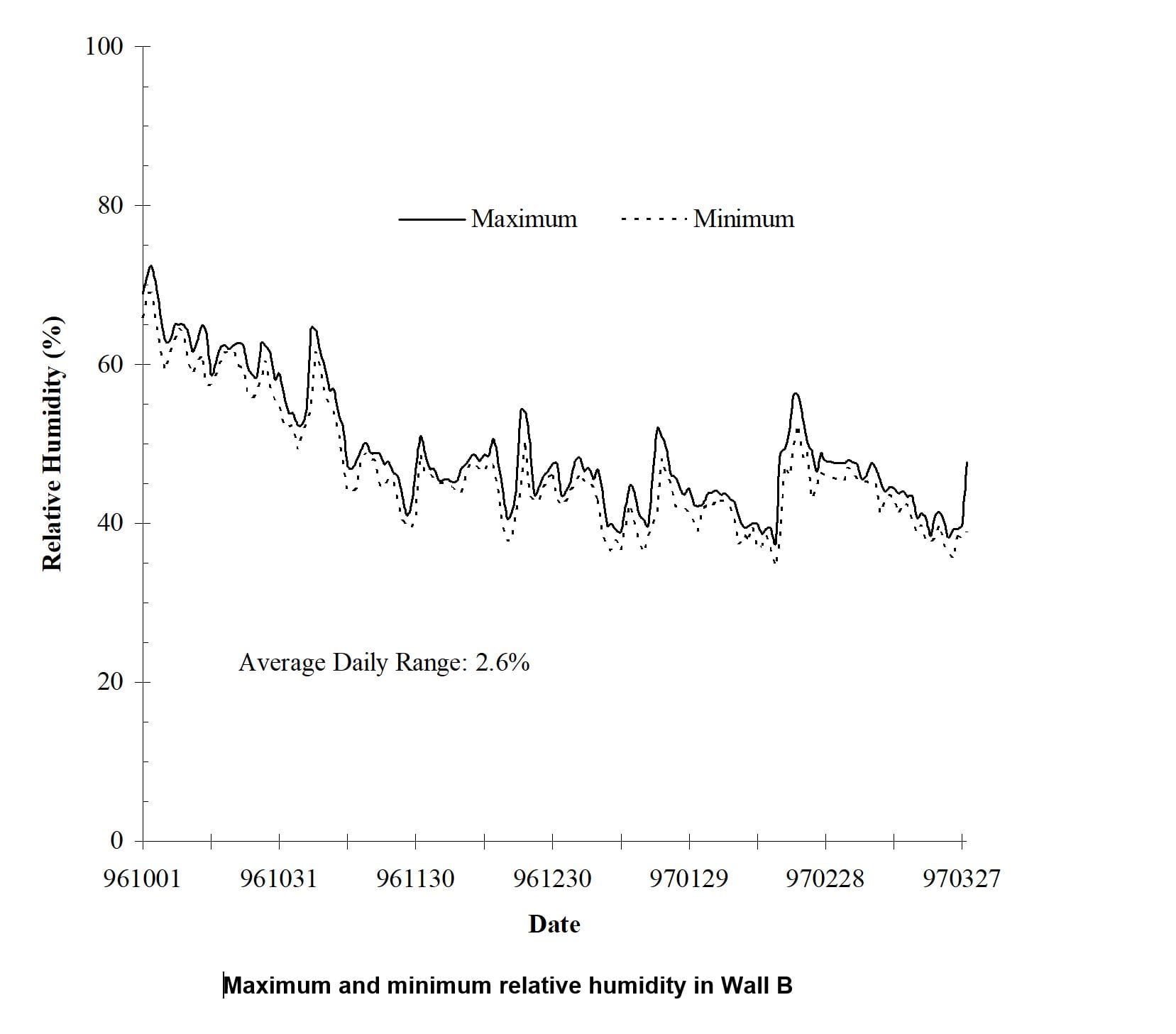

The Nexcem wall was intentionally designed to simulate a worst case scenario. The polystyrene on the exterior put the vapour barrier on the exterior (where it shouldn’t be) and the unpainted drywall ensured the movement of vapour into the wall system to get trapped by the polystyrene on the exterior. As you can see below, RH of Wall B (Nexcem) never comes close to approaching 100% (when condensation occurs). Wall A (conventional) however which was built correctly to simulate best case scenario, was nowhere near as resilient.

A comparison of the two plots clearly shows the humidity moderating effect within the Nexcem material of Wall B. Over the entire heating period, the daily RH variation (i.e., maximum less minimum) was 15.3% for Wall A and only 2.6% for Wall B.

An inspection of the relative humidity measurements in Wall B also shows that they never approached levels at which condensation might occur, even though there was no vapour retarder on the warm side of the wall, and despite a relatively impermeable outer sheathing. This data was collected over a winter in which the outdoor temperature dropped below -20 ºC (-4 ºF) several times. In fact, Wall A with a polyethylene retarder exhibited far more chance of condensation than Wall B. If the drywall had been painted, the Nexcem plastered, or the EXPS sheathing replaced with a more vapour permeable material, the RH in Wall B would have been even lower.

Furthermore, there are several other factors which make woodcrete ICF a sensible choice:

- Nexcem is made from mineralized recycled wood so it does not rot, ever.

- Nexcem woodcrete houses tend to use minimal steelwork, which is encased in concrete and wrapped in Nexcem. This acts as a vertical drain allowing any liquid moisture (if at all present) to drain down and away.

- Woodcrete creates an above average pH environment (alkaline) which inhibits mold formation. The hygroscopic nature of the material also draws moisture from the air, thus reducing the relative humidity and removing conditions in which mold can form.

- If water condenses and remains in a wall, it has the potential to freeze and expand. This action causes traditional blockwork to crack and then allow in more water. Nexcem has a more open matrix so is less susceptible to this phenomenon of frost shattering.

Nexcem woodcrete ICF is a recycled material with decades of global performance to demonstrate its ability to remove water quickly and avoid the other issues it can bring.

In Conclusion

Condensation within the wall of conventional homes are big risk potential. Using ICFs like Nexcem mitigate this risk to create a warm, healthy, clean and non-toxic living space.

If you want to build healthy, Nexcem insulated concrete forms (ICFs) are the only choice. Read here to learn more.