Winter may officially last three months, but cold climate builders grumble about chilly weather for a solid 5. Cold winter conditions greatly impact conventional concrete forming. With insulated concrete forms (ICFs), not so much.

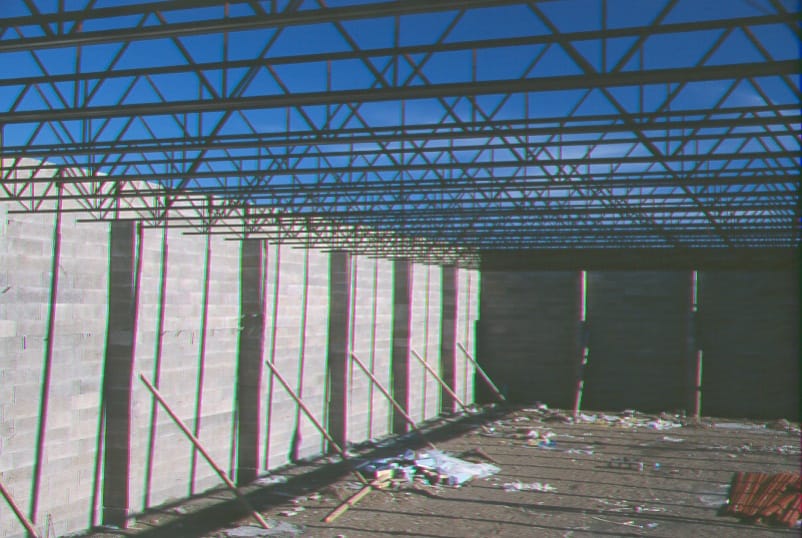

We’ll use a real example in the Thunder Bay, Ontario with the construction of 4 story arts and culture complex using Nexcem ICF. It started in late fall and continued in temperatures as low as -20°C (-4°F).

Despite the frigid conditions, the crew could keep concrete activities pretty much on a summer schedule thanks to the insulating power of Nexcem ICF walls.

Because the ICFs insulated the pour from the winter chill, concrete was kept at a proper curing temperature with only a foam board top cap, pre-drilled to accept and place the rebar dowels. An insulated tarp quickly placed over the top of the wall only.

The concrete was kept within the safe 10-30°C (50-86°F) range for curing with no need to insulate the sides of the wall or to heat the concrete artificially.

After only 48 hours, the foam board top caps and the tarp were removed and stored for future use, while construction moved on.

Construction Steps Saved

With conventional forming, the concrete would have been left exposed to the cold elements.

An entire day likely would have been spent insulating the pour with a tarp on both sides of the walls. Then, the concrete would have been heated by doing something like running pex tubing through the wall AND tying it to the rebar. And then, glycol would have been heated and run through the tubes, and afterward, the lines abandoned after the concrete was cured. What a waste!

Here’s what the typical grouting process was like for each level of the 4-floor building:

Tuesday:

- demising walls are poured

- tops of the demising walls are capped with pre-drilled Subterra panels and an insulated tarp

Thursday:

- hollow core slabs are installed, bearing on the demising walls

- an insulated tarp is placed over the hollow core slabs, as well as over the wall openings in the walls of the floor level below

- Because the envelope is so insulated, the floor below is heated with just 2 Herman Nelson heaters for the entire floor area.

- The heat rises and conditions the slab above for grouting.

Friday:

- the hollow core slabs are grouted

Monday:

- the grouted joints are now cured

- construction activities ready to proceed again on the grouted hollow-core floors

That pretty much resembles a summer routine except for the nominal additional costs of laying the tarp and heating with 2 Herman Nelson heaters.

Wrapping it up

If you build in Canada or the Northern United States , insulating and heating freshly poured concrete rarely seems like business as usual. With Nexcem ICF, it can be. By simply choosing ICF over traditional concrete forming and saving numerous winter construction steps, your winter and summer pours can be strikingly similar, both in terms of schedule and budget.